- Description

Production lead time: 30 days

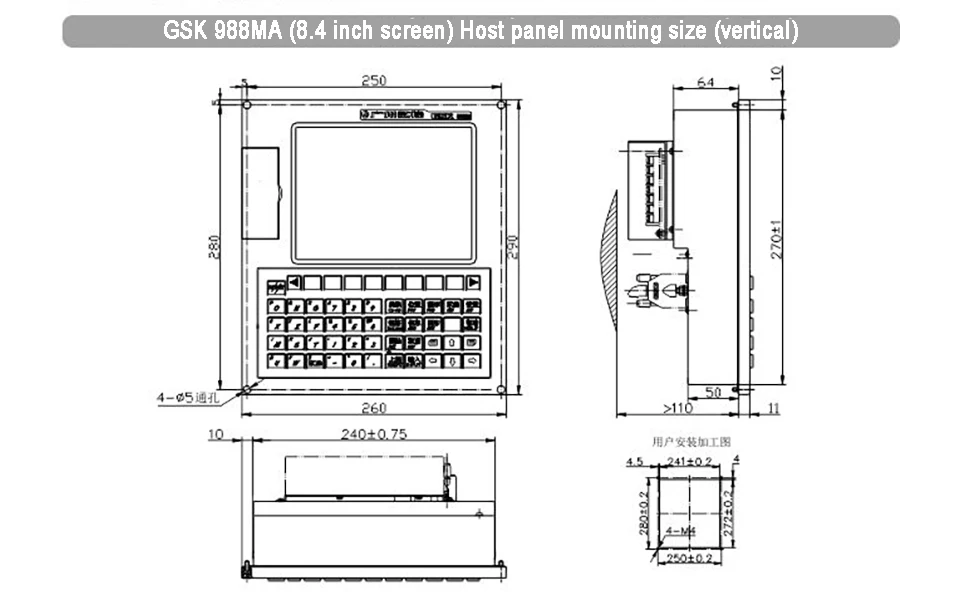

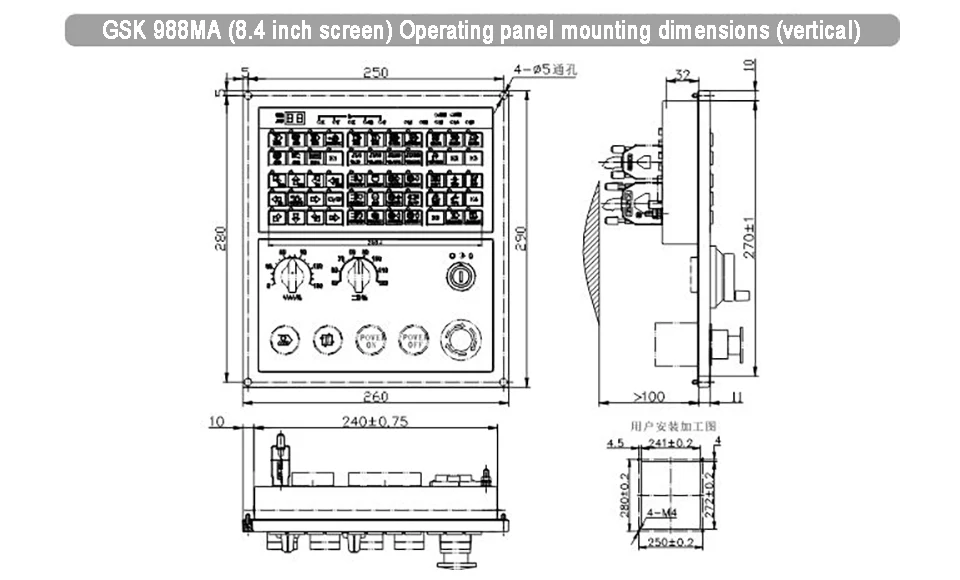

GSK 988MA series CNC machining center system

GSK 988MA series CNC system is a milling machining center CNC system based on dual-core hardware architecture. It supports gSK-Link industrial Ethernet bus with independent intellectual property rights to connect with servo drive unit and IO unit, and also supports EtherCAT bus, which is suitable for standard CoE interface servo and IO unit.Support speed look-ahead technology, high order spline fitting technology, support milling car composite processing, support blueprint programming function, programming guidance function, support perfect process help, support remote monitoring, etc., can meet the machining center application and mold processing application requirements.

(Note: detailed specifications, models, prices and other inquiries, please contact customer service to negotiate, do not directly place an order, otherwise not shipped)

●Feed axis: 6 axes

●CS axis: 3

●Encoder interface: 2 channels

●Handwheel: 2

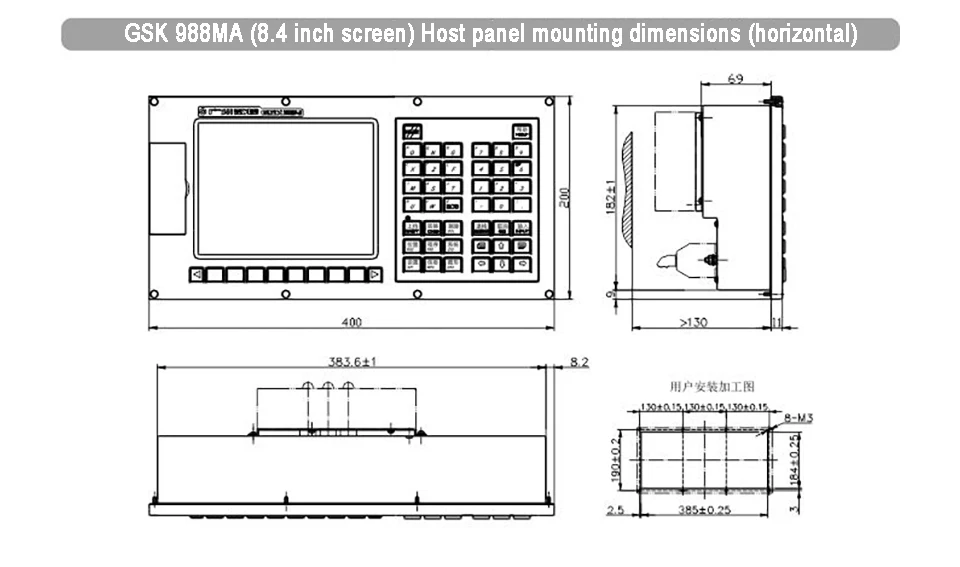

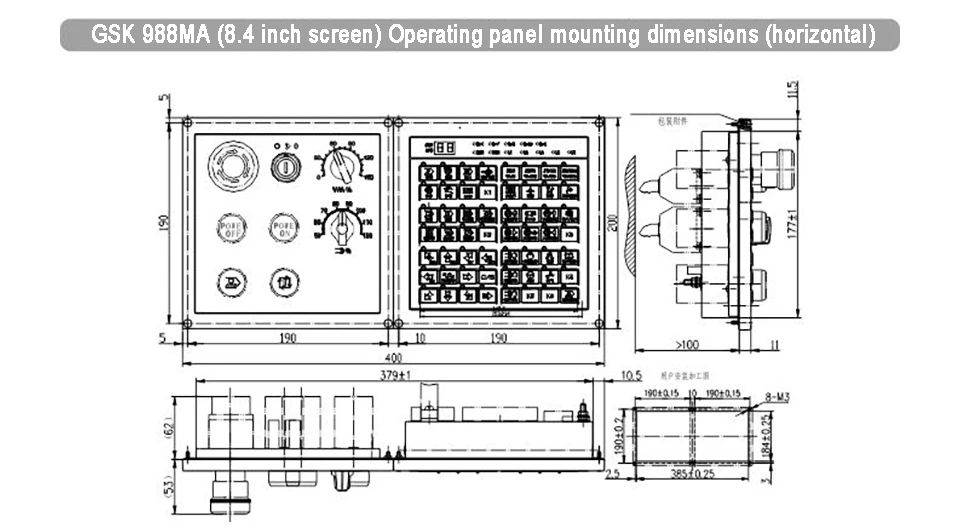

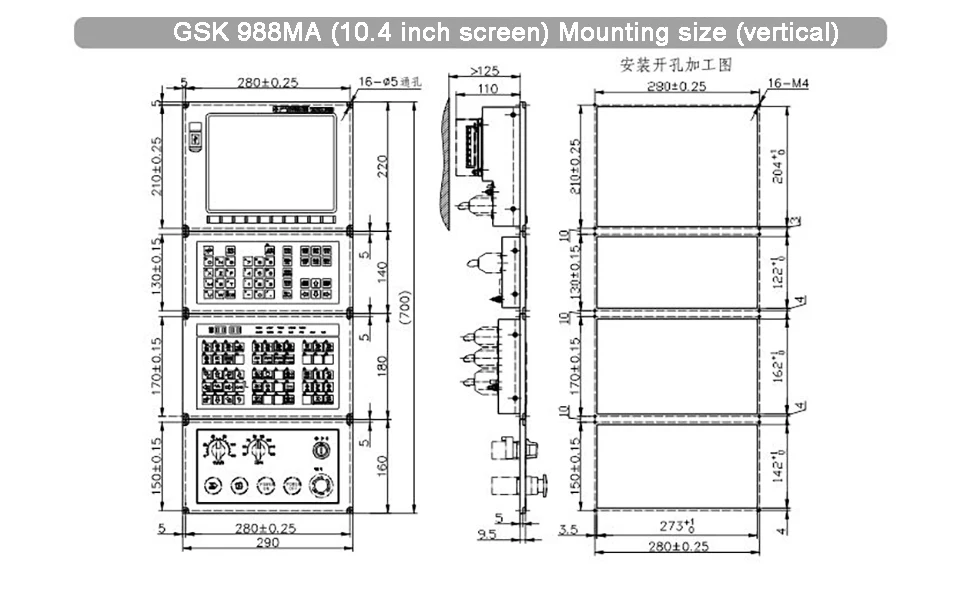

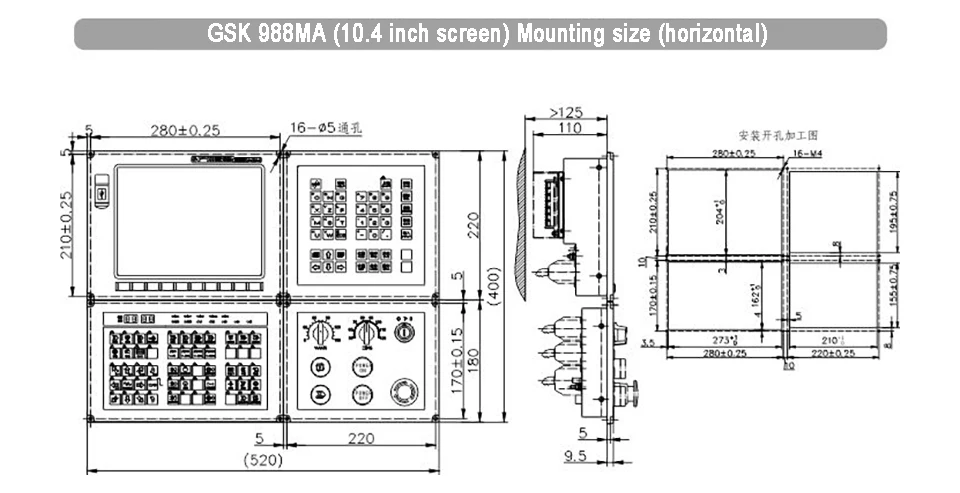

●LCD: 8.4 TFT 10.4 TFT

●interpolation period: 1ms;

●maximum speed: 100M / min (with 0.1um accuracy);

●support look ahead control technology

●support high-order spline fitting technology;

●support rich compound track cycle instructions, blueprint programming, programming guidance and process help

●support multi spindle control

●support feed axis synchronization;

●support seamless access of automatic production line and remote monitoring function;

●support three communication interfaces: RS232, USB and network to realize file transmission, DNC processing and USB online processing;

● it supports gsk-lnk Ethernet bus and EtherCAT bus. It supports 24 bit absolute encoder with high precision and no return to zero;

●support PLC online editing and compilation

●support hat type, disc type and other tool magazines;

●support statement macro program, and the programming is more concise;

●provide system debugging function to facilitate machine tool assembly and debugging; It supports on-line servo parameter modification and rigid tapping function debugging, has oscilloscope function, can intuitively analyze position / speed characteristic curve and roundness curve, and can record interpolation motion error data file.

USD

USD