- Description

सीएनसी नियंत्रक | सीएनसी प्रणाली | मिलिंग नियंत्रक | मशीनिंग केंद्र सीएनसी | सीएनसी नियंत्रण

उत्पादन लीड समय: भुगतान के बाद 20 कार्य दिवस

चीन से सभी सीएनसी मशीनों के लिए सीएनसी पार्ट्स उपलब्ध कराएं। यदि आपको वह सटीक मॉडल नहीं मिल सका जो आप चाहते हैं, तो आप उद्धरण प्राप्त करने के लिए तस्वीरें और लेबल paycnc@paycnc.com पर भेज सकते हैं।

Provide CNC parts for all CNC machines from China. If you could not find the exact model that you want, you can send photos and label to paycnc@paycnc.com to get quotation

CNC system of GSK 980MDc drilling and milling machine

5 axis 5 linkage control, with horizontal, vertical and separate three types of structure.Adopt 8.4 "color LCD, support ladder diagram online monitoring, online drilling CAM function, online programming wizard, automatic programming plane milling, automatic center point and other functions.Support I/O unit expansion, can be adapted to disc type knife library and hat type knife library, to meet the needs of machining centers and special machine tools.

Cost-effective GSK980MDc series products are universal machining center, CNC milling machine, drilling machine the best partner!

(Note: detailed specifications, models, prices and other inquiries, please contact customer service to negotiate, do not directly place an order, otherwise not shipped)

Product features

● 5 axes 5 linkage Control;

● the minimum control accuracy is 0.1um and the maximum moving speed is 60m / min;

● GS2000T-N series strong overload servo unit is equipped as standard, and 5000 line encoder is used for servo motor position feedback;

● it can realize spindle orientation, rigid tapping, cylindrical interpolation and indexing table control;

● built in PLC, ladder diagram online display and real-time monitoring, support o-unit expansion, and can be adapted to disc type and hat type tool magazine;

● it has the functions of on-line drilling cam, on-line programming guide, automatic programming of plane milling, automatic workpiece center finding, etc., which is convenient for programming and fast operation;

● it supports 54 workpiece coordinate systems, coordinate rotation, scaling, mirroring, automatic chamfering and sentence macro instructions, and provides 12 fixed cycle instructions and 23 compound cycle instructions, with flexible and simple programming;

● 40m program storage space, 10000 part programs, supporting ∪ disk program processing and serial communication DNC processing;

● level 6 operation authority management, 32 time limited shutdown settings;

● 8.4-inch true color CD, supporting Chinese, English, Russian and other multilingual displays.

Product parameters

| Man machine page |

| 8.4-inch true color LCD, 7 soft function keys |

| Support Chinese, English, Russian and other languages |

| The processing track is displayed, and the processing track is enlarged, reduced, translated and the viewing angle is switched in real time |

| Position, program, tool compensation, alarm, parameter, setting, graphics, diagnosis, ladder diagram |

| Operation management |

| Operation mode: edit, automatic, input, mechanical zero return, manual pulse single step, manual, DNC |

| Level 6 operation authority management; 32 time limited shutdown |

| Program switch, parameter switch |

| Communication function |

| USB: USB disk file operation, direct processing of USB disk files, and support PLC program and system software USB disk upgrade |

| RS232: bidirectional transmission of part programs, parameters and other files, supporting PLC program update |

| Program storage and editing |

| Full screen editing; Program capacity: 40m, 10000 programs (including subroutines and macro programs) |

| MD | it is allowed to input and run 8 program segments |

| It supports macro program subroutine calling and allows 4-fold subroutine nesting |

| Calculator, online programming wizard |

| Simplify programming functions |

| Fixed cycle, compound cycle, drilling cycle, rigid tapping, automatic chamfering, sentence macro instruction programming, indexing function of indexing table |

| Compensation function |

| Reverse clearance compensation: 0mm-2mm (or 0inch-0.2inch). The reverse clearance compensation mode and frequency are set by parameters |

| Memory pitch error compensation: a total of 1024 compensation points, and the number of compensation points of each axis is set |

| Tool function |

| Tool length compensation (tool offset): 32 groups; Tool wear compensation: 32 groups |

| Tip radius compensation (type C) |

| Auxiliary function |

| Special m codes (M00, M01, M02, M30, M98, M99) · other m codes are defined by PLC |

| PLC function |

| Two level PLC program, 5000 steps at most, and the refresh cycle of level 1 program is 8ms |

| PLC program online display and real-time monitoring; Support PLC warning and PLC alarm |

| Multiple PLC programs can be stored, and the currently running PLC program is selected by parameters. The standard PLC program supports disc magazine and hat magazine |

| Basic I / O: 41 inputs 36 outputs |

| Expandable serial O unit (optional): I / oa-01t: 24 point input, 16 point output, 4-channel analog voltage output |

|

IOA-02T:40 point input, 24 point output, 8-Channel analog voltage output and 4-channel analog voltage input |

| Spindle function |

| Spindle speed: it can be given by s code or PLC signal, and the speed range is 0rpm-9999rpm |

| Spindle magnification: 50% ~ 120%, a total of 8 levels of real-time repair and adjustment |

| 2 channels of 0V ~ 10V analog voltage output |

| Support analog spindle m-shift and τ Type shift function, flexible tapping, rigid tapping |

| 1 channel spindle encoder feedback, the number of spindle encoder lines can be set (0 or 100p / R ~ 5000P / R) |

| Control number axis |

| Maximum control axis: 5 axes |

| Maximum number of linkage axes: 5 axes (linear interpolation), 3 axes (spiral interpolation), 2 axes (arc interpolation) |

| Coordinate value (system) and size |

| Local coordinate system, machine tool coordinate system, workpiece coordinate system 1-6 (G54-G59), additional workpiece coordinate system (P1 ~ p48) |

| Position command range: ± 9999999999x minimum input unit |

| Absolute / incremental programming, English / metric conversion, linear axis / rotary axis |

| Preparation function |

| eighty-five individual G instruction, including fast positioning, interpolation, automatic chamfering, tool compensation, metric and British system input, coordinate rotation, scaling, mirroring, sentence macro instruction, macro program call, jump, cycle instruction, etc |

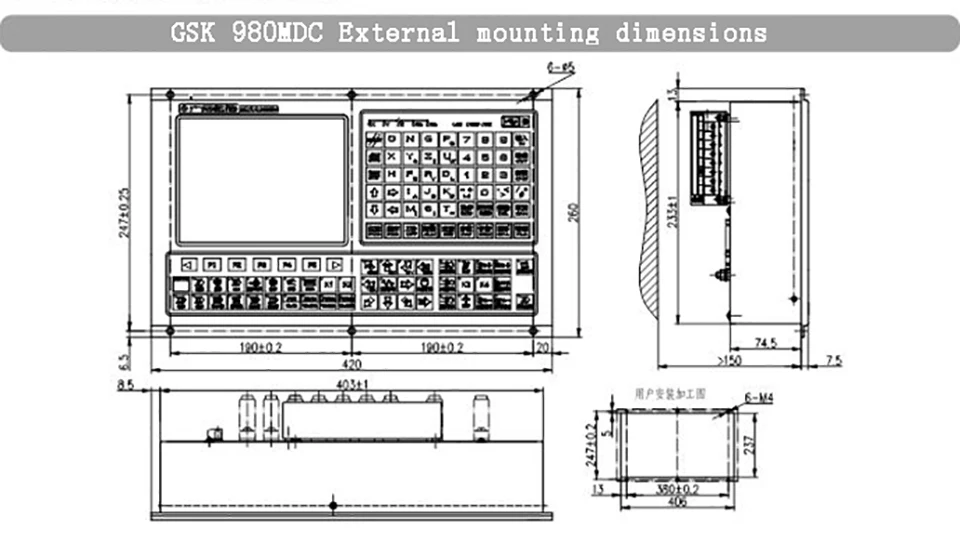

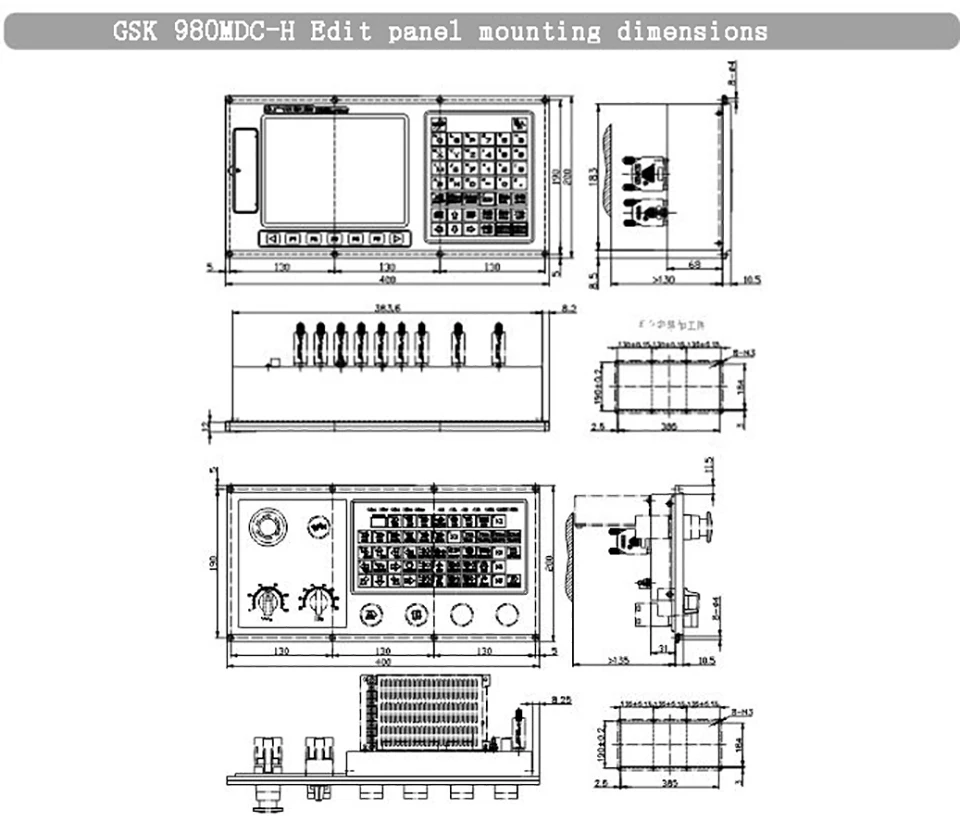

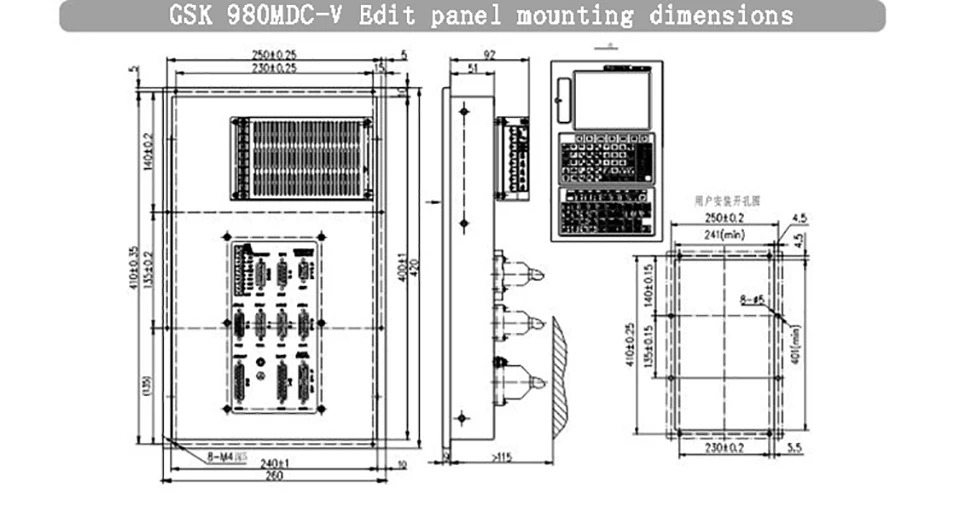

Product installation dimensions

USD

USD