- Description

Production lead time: 25 days

GSK980MDi_CNC_Milling_Machine_Controller_User_Manual(PDF file, size 17.1MB)

CNC system of GSK 980MDi drilling and milling machine

GSK 980MDi is based on GSK-Link industrial Ethernet bus control technology, standard bus type servo drive unit and absolute encoder servo motor, realizing 5 axis 5 linkage, minimum instruction unit 0.1um.Support servo parameters online configuration, servo status online monitoring and other functions.It has CAM function of on-line drilling and milling groove, on-line programming wizard, automatic programming of plane milling and so on.Supports I/O expansion through GSK-Link bus, and can be adapted to disk and hat knife libraries to meet the needs of machining centers and special machine tools.

(Note: detailed specifications, models, prices and other inquiries, please contact customer service to negotiate, do not directly place an order, otherwise not shipped)

|

Number of control axes |

Maximum number of control axes: 5 axes (optional 6 axes) |

|

Number of PLC control axes: 5 axes |

|

|

Maximum number of linkage axes: 5 axes (linear interpolation), 3 axes (spiral interpolation), 2 axes (arc interpolation) |

|

|

Coordinate value (system) and size |

Local coordinate system, machine tool coordinate system and workpiece coordinate system 1-6 (g54 ~ G59) |

|

Coordinate plane selection |

|

|

Position command range: ± 9999999 × Minimum input unit |

|

|

Absolute / incremental programming, English / metric conversion, linear axis / rotary axis |

|

|

Preparation function |

85 g instructions, including fast positioning, interpolation, automatic chamfering, tool compensation, metric and British system input, coordinate rotation, scaling, mirroring, sentence macro instructions, macro program call, jump, cycle instructions, small segment forward-looking, etc |

|

Feed function |

Fast moving speed: 0mmmn ~ 100000mm / min |

|

Fast magnification: F0, 25%, 50% and 100% four levels of real-time adjustment |

|

|

Cutting feed rate: 0mm / min ~ 15000 mm / min |

|

|

Feed rate: 0 ~ 150%, 16 levels in total, real-time adjustment |

|

|

Bus function |

Servo motor adapted to multi turn absolute position encoder |

|

The absolute coordinate system is automatically restored after the machine tool is powered off |

|

|

Mechanical zero return of machine tool without stop |

|

|

Online modification of servo parameters |

|

|

Servo status online diagnosis |

|

|

Operation log |

|

|

Remote monitoring and fault diagnosis function |

|

|

Spindle function |

Spindle speed: it can be given by s code or PLC signal, and the speed range is orpm ~ 9999rpm |

|

Spindle magnification: 50% ~ 120%, a total of 8 levels of real-time repair and adjustment |

|

|

2 channels of 0 ∨ ~ 10V analog voltage output |

|

|

Support analog spindle m-shift and τ Type shift function, flexible tapping / rigid tapping |

|

|

2-way spindle encoder feedback, the number of spindle encoder lines can be set (0 or 100p / R ~ 5000P / R) |

|

|

Tool function |

Tool length compensation (tool offset): 32 groups |

|

Tool wear compensation: 32 groups |

|

|

Tip radius compensation (type C) |

|

|

PLC function |

Two level PLC program, 5000 steps at most, and the refresh cycle of level 1 program is 8ms |

|

13 basic commands and 31 functional commands |

|

|

PLC program online display and real-time monitoring; Support PLC warning and PLC alarm |

|

|

Basic I / O: 48 inputs / 38 outputs |

|

|

Expandable serial I / O unit (optional): or-44t: 48 point input, 32 point output, 4-channel analog voltage output |

|

|

Auxiliary function |

Special m codes (M00, M01, M02, M30, M98, M99), and other m codes are defined by PLC |

|

Program storage and editing |

Program capacity: 64M, 10000 programs (including subroutines and macro programs) |

|

Editing method: full screen editing |

|

|

Editing functions: program segment word retrieval, modification, deletion, copy and paste |

|

|

MDI allows you to input and run 8 program segments |

|

|

Support macro program / subroutine calling, and allow 4-fold subroutine nesting |

|

|

Calculator, online programming wizard, online drilling cam function, automatic programming function of plane milling |

|

|

Program check function |

Track preview, graphic simulation, idle operation, machine tool lock, auxiliary function lock, single section operation |

|

Simplify programming functions |

Fixed cycle, compound cycle, drilling cycle, rigid tapping, automatic chamfering, sentence macro instruction programming, indexing function of indexing table |

|

Compensation function |

Reverse clearance compensation: 0mm ~ 2mm (or 0 inch ~ 0.2inch). The reverse clearance compensation mode and frequency are set by parameters |

|

Memory pitch error compensation: a total of 1024 compensation points, and the number of compensation points of each axis is set |

|

|

interface |

Support Chinese, English, Russian and other languages |

|

The processing track is displayed, and the processing track is enlarged, reduced, translated and the viewing angle is switched in real time |

|

|

Position, program, tool compensation, alarm, parameter, setting, graphics, diagnosis, ladder diagram |

|

|

Communication function |

USB: ∪ disk file operation, ∪ disk file direct processing, support PLC program and system software ∪ disk upgrade |

|

RS232: bidirectional transmission of part programs, parameters and other files, supporting PLC program update |

|

|

LAN: remote file transfer |

|

|

Electrical grounding |

48 / 38 point digital input / output interface, 2-way encoder interface, 2-way handwheel interface, 2-way spindle analog interface, RJ45 network port and gskl Ⅰ NK network port |

|

Safety function |

Emergency stop, hardware travel limit, software travel check, data backup and recovery |

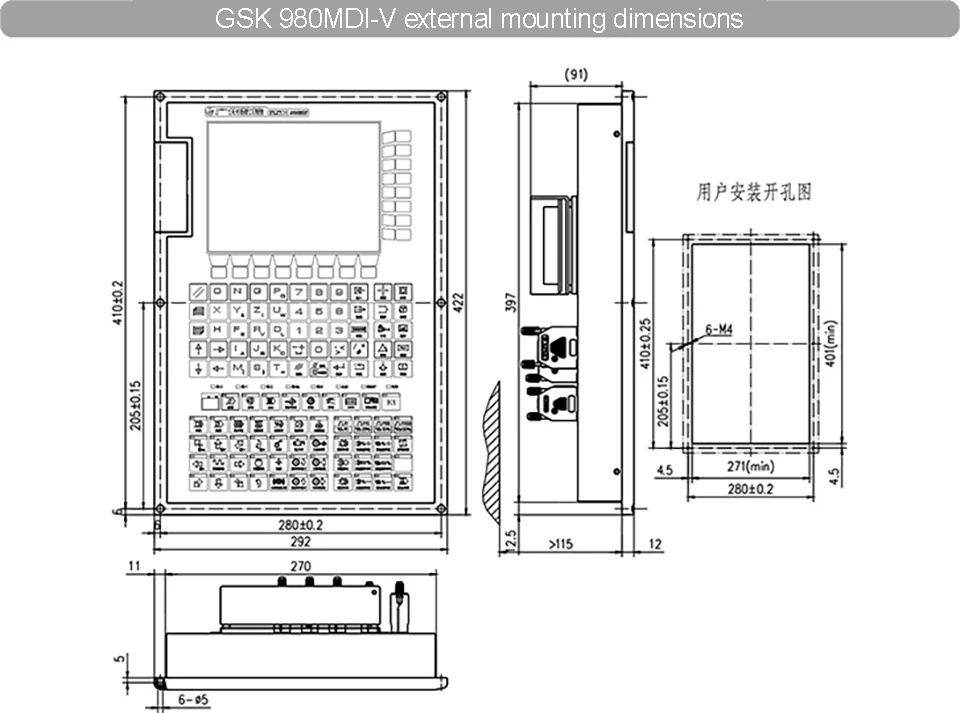

■New appearance structure, double row soft function keys

■GSK Link Industrial Ethernet bus control

■5-axis 5 linkage control, minimum control accuracy 0.1 μ m. Maximum moving speed 100M/min

■Online cam function

■It supports on-line servo parameter configuration,real-time servo status monitoring and mechanical zero return without stop

■It has the functions of programming wizard and automatic programming of plane milling

■It supports I / O unit expansion and can be adapted to disc and hat magazine

■Bus type strong overload servo unit is equipped as standard,and 17 bit line encoder is used for servo motor position feedback

■The bus type spindle servo drive unit can realize spindle orientation, rigid tapping,cylindrical interpolation and indexing table control

USD

USD