Transformation and Application of GSK 990MC CNC System on Sharpening Machine

The number of system control axes is 3 (the belt machine is 2);

Realize the function editing function of the sharpener;

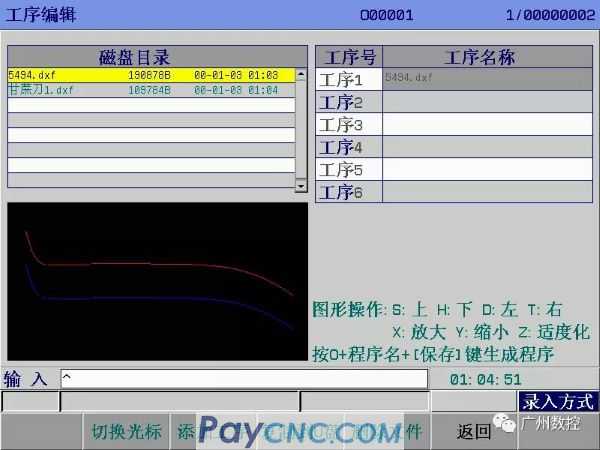

Implement DXF drawings into CNC to generate processing programs;

Realize the function of automatic grinding wheel and segmented compensation of the sharpening trajectory。

solution

Use 990MC control for function development on V1.5MDJ version;

Add the function of importing computer-edited DXF graphics into the CNC system, and the system automatically generates the sharpening program function;

Increasing each segment of the sharpening track can perform segmented compensation corresponding to the axis;

Add sharpening multi-process editing function, can arrange multi-process machining online.

Application effect

Import the DXF chart into the CNC system to automatically generate the sharpening program, saving time for manual editing in the system panel;

Process editing and segment compensation can shorten the effective time of workpiece production and improve production efficiency;

Dedicated interface, concise and convenient, customers only need to fill in relevant variables, and can automatically generate processing programs;

It can realize the grinding processing of various types of sharpening knives and realize the diversification of processed products.

USD

USD