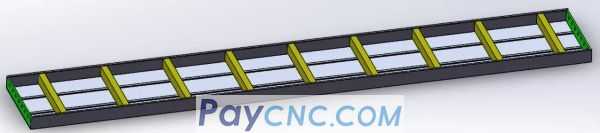

Aluminum mold welding with RH06 Robot

The robot replaces the welder for welding, and the workpiece is manually loaded and unloaded, and the welding is completed by one clamping;

The maximum width of the workpiece is 400mm, the maximum length is 3000mm, and the minimum wall thickness is 3mm;

The workpiece needs to be welded diagonally alternately to reduce the amount of deformation, and the flatness of the workpiece is +/-1mm.

2 solution

The project is composed of 2 RH06 welding robots, 2 gun cleaning and wire cutting mechanisms, 2 sets of welding tooling, 2 automatic welding power supplies, 2 sets of automatic anti-collision welding guns, etc.;

Due to the long workpieces, the project uses two robots to weld at the same time, with H-type two-station layout;

Due to the high deformation requirements of the workpiece, a water circulation cooling device was installed on the tooling;

In order to ensure the stability and continuity of welding, the project is equipped with a gun-cutting mechanism.

3Application effect

The double station layout can be continuously welded for a long time, and the welding quality is significantly improved;

The tooling realizes the clamping of the workpiece at a time, and the two robots are welded diagonally, so that the amount of deformation is effectively controlled;

The welding industry is a high-risk industry. High temperature, arc light and welding fumes have a certain impact on the physical and mental health of workers;

The application of welding robots in the welding industry is the general trend, which is not only the market promotion, but also the requirements for technological upgrades.

USD

USD