How to set zero point of encoder on GSK SJT servo motors

Under normal circumstances, when the servo motor leaves the factory, the company's motor trial production personnel have

Adjust the zero crossing of the motor encoder (R. in CO-RDY: within plus or minus 20).The zero adjustment of the servo motor encoder refers to: the servo motor is faulty or special in the encoder

In the case of the operation, please take some examples as follows:

1. During the installation of the servo motor, the customer knocked hard on the encoder of the servo motor

The mandrel and the back cover cause the encoder to be broken. At this time, the servo drive (take DA98A as

Example) The upper alarm is ERR-9 or ERR-32, which needs to be performed when replacing the encoder

Zero.

2. The servo motor is used under overload conditions. The encoder is burned out due to overheating of the motor.

When the encoder is replaced, zero adjustment is required.

3. During the use of the servo motor, the waterproof protection measures are inappropriate, and the liquid enters the code

The encoder plug causes the encoder to short-circuit and burn out.

Zero.

4. The quality of the encoder itself, at this time when the encoder is replaced, zero adjustment is required.

In the above four cases, the servo motor needs to perform encoder zero adjustment.

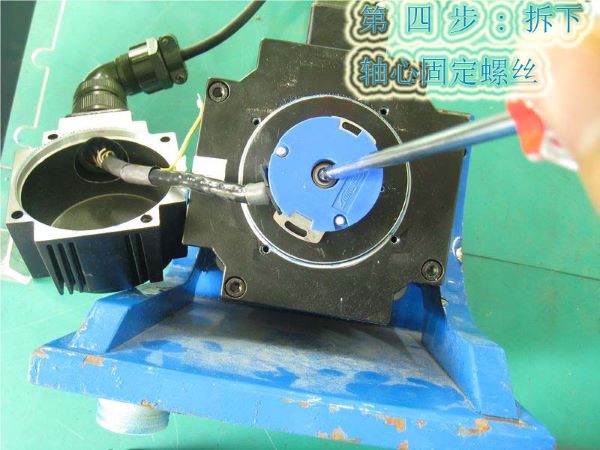

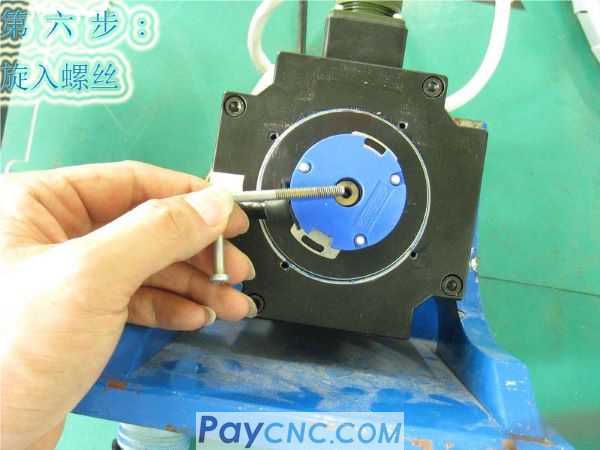

Illustration of zero adjustment of feed shaft motor encoder

USD

USD