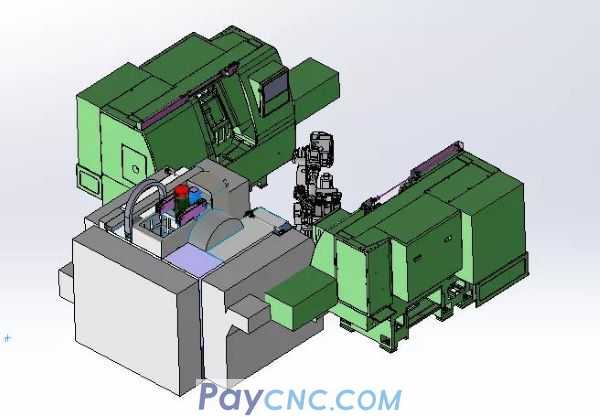

GSK RB50 Robot working with Bochi CNC Lathe machine

The rough weight is 9kg, which can replace laborious and long-time labor;

Matching the workpiece technology, the robot is docked with 3 processing equipment to realize the automatic loading and unloading of CNC machine tools.

solution

Design 1 set of special loading bin and 1 set of secondary positioning tooling for workpiece to realize automatic accurate positioning of incoming material;

Use 1 RB50 robot, with 3 CNC machine tools in the font layout, match a set of loading and unloading double grippers and a set of reversing mechanism to realize stable and efficient automatic loading and unloading operations.

Application effect

One robot replaces 4 manual machine tool loading and unloading operations, saving labor input;

The entire robot loading and unloading system has a compact layout, which improves the site utilization rate;

The robots have a 1-to-3 fret layout, which runs alternately. The production cycle is closely matched and runs smoothly;

The finished product is directly unloaded to the finished product frame, which reduces the number of manual turnover operations on the workpiece.

USD

USD